In modern industrial operations, companies are constantly seeking ways to improve flexibility, efficiency, and durability in their infrastructure. Traditional materials such as steel or wood often fail to meet the evolving demands of today’s industrial environments. Aluminium modular sections provide a versatile, strong, and durable solution for various industrial applications. From machine frames and workstations to safety enclosures and conveyor systems, these profiles are transforming how industries implement structural solutions efficiently and reliably.

Strength and Lightweight Construction

A primary advantage of aluminium modular sections is their exceptional strength-to-weight ratio. Aluminium alloys are engineered to carry heavy loads while remaining lightweight, making them easy to handle, transport, and install. Unlike steel, aluminium does not add unnecessary weight to structures, reducing stress on foundations and lowering overall construction costs.

This combination of strength and lightness is especially valuable for machine frames, conveyor supports, workstations, and safety enclosures, where stability is crucial, yet heavy materials would make assembly cumbersome. Lightweight profiles also simplify relocation or reconfiguration of structures as production requirements change.

Modularity and Ease of Assembly

One of the defining features of aluminium modular sections is their modularity. Profiles are designed with standardized slots and channels that allow for flexible assembly without welding. Components can be connected quickly using bolts and nuts, making construction straightforward and reducing installation time.

This modular approach is ideal for industries that frequently adjust their layouts. Workstations, conveyor lines, safety barriers, and enclosures can all be modified with minimal disruption to ongoing operations. The modular design also allows profiles to be reused, which maximizes cost efficiency and reduces material waste. Furthermore, industrial facilities can scale systems up or down as production demands evolve, making aluminium modular sections a future-ready solution.

Customization for Specific Applications

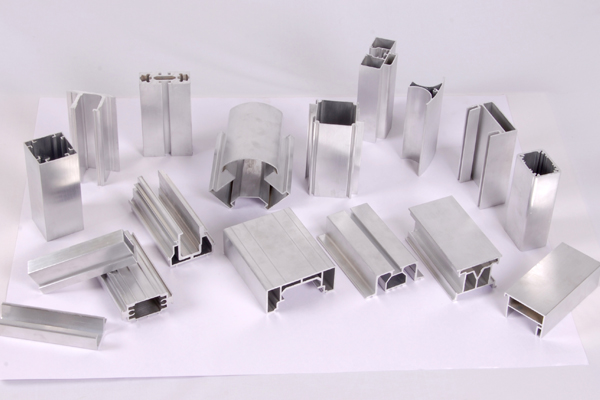

Aluminium modular sections offer unmatched customization options. Profiles can be extruded in different shapes, sizes, and cross-sections to meet specific project requirements. Engineers can choose from channels, beams, and T-slot profiles to design frameworks tailored to their operational needs.

Customization also extends to surface finishes. Profiles can be anodized, powder-coated, or painted, enhancing durability and providing an aesthetic appeal suitable for visible workstations or machinery enclosures. By providing exact specifications, aluminium modular sections minimize over-engineering and material waste, allowing industries to build efficient structures without compromise.

Faster Installation and Reduced Labor Costs

Traditional steel or welded frameworks often require skilled labor, cutting, welding, and coating, all of which are time-consuming and expensive. Aluminium modular sections significantly reduce labor requirements because of their easy assembly process. Standard hand tools are sufficient to construct complex frameworks, which saves both time and money.

Additionally, any modifications, relocations, or expansions can be performed without specialized equipment. This reduces downtime in production facilities, which is crucial for industries where time directly impacts operational efficiency and profitability. The ability to quickly assemble, reconfigure, or expand structures gives companies a competitive advantage in dynamic industrial environments.

Durability and Low Maintenance

Durability is a key advantage of aluminium modular sections. Aluminium naturally forms a protective oxide layer, which protects it from corrosion, moisture, and environmental stresses. Unlike steel, aluminium does not rust, even in humid or industrial environments, ensuring that structures maintain their integrity and appearance for years.

Low maintenance requirements reduce operational costs over time. Unlike traditional steel, which may need regular painting, coating, or repair, aluminium modular sections remain functional with minimal intervention. Their long service life and consistent performance make them a cost-effective solution for industries seeking reliable and sustainable structural systems.

Sustainability and Environmental Benefits

Sustainability has become a priority in modern industrial operations. Aluminium is fully recyclable and can be reused without losing strength or quality, making aluminium modular sections environmentally responsible. Industries can reduce waste and minimize the environmental impact of their operations by opting for aluminium solutions.

Lightweight aluminium profiles also lower transportation energy requirements, further reducing the carbon footprint. Their long lifespan and adaptability contribute to sustainable manufacturing practices, aligning with eco-conscious industrial strategies. Companies that invest in aluminium modular sections benefit from durability and efficiency while supporting green initiatives.

Versatility Across Industrial Applications

Aluminium modular sections are used in a broad range of industrial applications. They are suitable for machine frames, conveyor systems, safety enclosures, workstations, and storage frameworks. Additionally, they can be applied in partitions, clean-room setups, automation structures, and protective barriers.

The versatility of aluminium modular sections allows engineers to design frameworks that are both functional and flexible. They support heavy equipment, house electrical components, and create safety zones, providing an all-in-one structural solution for various industrial settings. Their adaptability makes aluminium modular sections a practical choice for industries with evolving operational requirements.

Cost-Effectiveness Over the Lifecycle

While the initial cost of aluminium modular sections may be higher than basic steel or wood, their long-term advantages make them a cost-effective choice. Faster assembly reduces labor expenses, while durability and low maintenance minimize replacement and repair costs. The reusability of modular profiles further reduces expenditure, especially in facilities with frequent reconfigurations or expansions.

When evaluating the total cost of ownership, aluminium modular sections often outperform traditional materials. Industries gain both efficiency and flexibility, making them a smart investment for sustainable and reliable industrial infrastructure.

Enhanced Safety and Operational Efficiency

Safety is a critical consideration in industrial environments. Aluminium modular sections allow for the creation of safety enclosures, barriers, and protective guards tailored to specific machinery or hazardous areas. These structures can be modified easily as requirements change, ensuring worker protection without disrupting production processes.

Operational efficiency is improved through customized workstations, optimized layouts, and integration with automated systems. The adaptability of aluminium modular sections enables streamlined workflows, better maintenance access, and easy integration of modern industrial technology, which collectively enhance productivity and workplace safety.

Conclusion

Aluminium modular sections provide industrial applications with unmatched benefits, including lightweight strength, modularity, customization, rapid assembly, durability, sustainability, versatility, cost-effectiveness, and improved safety. These profiles enable companies to create high-performance, adaptable, and long-lasting structures that meet both operational and environmental objectives.

Partnering with JM Aluminium provides industries with premium aluminium modular sections, fully customized designs, and expert technical support. Their solutions enable efficient, durable, and adaptable industrial structures, helping businesses improve productivity, lower operational costs, and maintain long-term performance. With JM Aluminium’s expertise, companies achieve reliable, flexible, and high-quality outcomes for every industrial project.